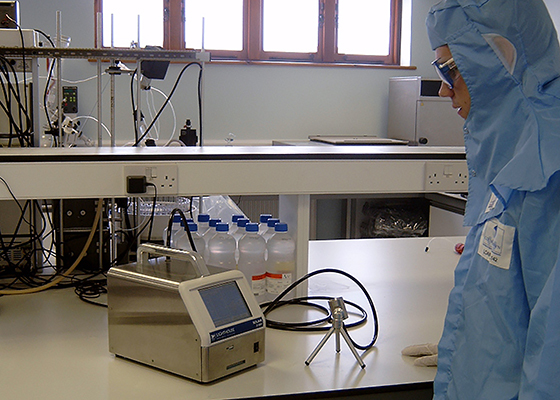

Enbloc’s experienced cleanroom validation team can carry out all environmental performance testing for your cleanrooms, containment suites, Microbiological Safety Cabinets, Laminar Flow Cabinets and associated environment services including fridges and freezers, to meet the requirements of BS EN ISO 14644 and EU cGMP.

Our in-house engineers are CTCB trained and have years of onsite experience performing complete cleanroom testing and validation.

We have developed an online quotation feature. By filling in the adjacent form and clicking submit an instant quote will be generated and forwarded to your email address provided.

Should the email not arrive please check your email address and resubmit. The quote shouldn’t take more than a few minutes to arrive in your inbox.

If you have multiple rooms of the same classification please add the room areas together and submit as a total area.

Please rest assured that we do not share your data with a 3rd party.

Please complete all fields.

Being a design and build contract, Enbloc have the knowledge and experience to write and execute your URS, SAT, FAT, DQ, IQ and PQ protocols, ensuring the validation master plans are followed.

We can carry the below testing and validation tests in accordance with your specifications whilst ensuring own standards of operating are met.

Enbloc’s validation engineers can carry out on site temperature and humidity mapping of cleanrooms and cleanrooms associated services of any size, this might be a small fridge, or a 2000m² cleanroom. Enbloc have temperature and humidity mapping software as well as a variety of different loggers.

Allow Enbloc to create and execute your temperature mapping validation as well as completing periodical re-validation, ensuring your facility is continuing to perform inline with your design parameters.

Microbiological Safety Cabinets and Laminar flow cabinets are an integral part of your cleanroom manufacturing process. As well as the cleanroom HVAC validation, our engineers are fully trained in the testing, commissioning and ongoing compliance for all Class I, II and III cabinets as well as laminar flow cabinets.

This rounded expertise allows to minimum downtime within your cleanroom with no need to arrange various validation contractors.

Environmental monitoring forms an important part of cGMP Annex 1. Enbloc’s engineers can complete settle plate, contact plate and active air testing within your cleanroom periodically as required. Our on-site laboratory partner allows us to ensure quick turn around with reporting and results.

© 2025 Enbloc Ltd. All rights reserved | Enbloc Ltd, Registered Office: Unit 2, Pale Lane, Hook, Hampshire, RG27 8DH. Registered in England - Company No. 04079907